askPixi is a conversational, location-aware AI for manufacturing and logistics. It connects real-time location data with ERP, MES, WMS, data lakes, file systems, and other planning sources to predict issues, explain root causes, and trigger the right actions before performance is impacted. Think of it as your operations co-pilot that sees across all systems and acts before a bottleneck or disruption reaches your desk.

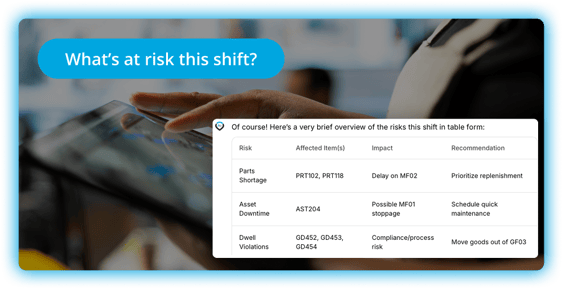

askPixi, what's at risk this shift?

How askPixi Improves Daily Operations

- Early Warning

Detect issues before they slow down performance. - Understand Root Cause + Next Step

Explains why something is slowing down and recommends the next logical action in plain language. - Targeted Action Within Guardrails

Adjusts schedules, reallocates resources, or initiates maintenance automatically and acts within your defined thresholds — roles, zones, and time windows — with full audit trails and approvals.

Expected Business Impact

↓ 20-30%

Cycle Time

Shorter production loops

and faster turnaround

↓ 25%

Unplanned Downtime

Early detection of bottlenecks

and disruptions

↓ 50-60%

Planning Effort

AI-driven scheduling and

shift optimization

↓ 10-15%

Working Capital

Improved material flow and

delivery predictability

Validated with representative manufacturing data and digital twin testing environments.

Join the Early Access Program

Bring askPixi™ into your production environment. Our Early Access Program is designed for a seamless integration into your existing systems, allowing you to stabilize schedules and free up planning time as you transition to live operations. As a participant, you’ll receive dedicated engineering support and priority onboarding to ensure a smooth roll-out and early access to our latest features.

Use Cases: Where askPixi Delivers Impact

.png?width=495&height=320&name=NO-GLOW-Inline-Image%20(1).png)

On-Time Delivery Protection

Prevents delays by identifying risks early and adjusting orders, resources, and routing before timelines slip.

.png?width=495&height=320&name=NO-GLOW-Inline-Image%20(2).png)

Real-Time Bottleneck Detection & Reprioritization

.png?width=495&height=320&name=NO-GLOW-Inline-Image%20(3).png)

Adaptive Shift & Capacity Planning

.png?width=495&height=320&name=NO-GLOW-Inline-Image%20(4).png)

Predictive Material Flow & Bottleneck Avoids

FAQs

-

What is askPixi?

-

Is it ready for production environments, and how quickly will we see results?

Yes. askPixi is production-ready from day one. Through the Early Access Program, selected sites can connect it to their RTLS, MES, WMS, and ERP systems and start running real use cases within days with full support from our team. Most plants see impact fast with fewer delays, less firefighting, and more stable schedules within the first weeks.

-

Does it replace our MES, WMS, or ERP?

No. askPixi works alongside them. If your MES shows a machine is down, askPixi™️ checks where the spare parts are, whether another line can take over, and pushes the updated plan to the shop floor in minutes.

It adds foresight and cross-system actionability that your core systems cannot provide alone.

-

How does it detect problems before they escalate?

askPixi monitors key metrics in real time such as cycle times, part arrivals, queue lengths, and inventory coverage.

If a trend points to a likely delay, for example a supplier truck running late with buffer stock already low, it alerts you with the cause and suggests or triggers corrective action before production is impacted.

-

Can it act automatically?

Yes. You decide the level of autonomy. Some teams start with approval-based alerts. Others allow askPixi to execute certain playbooks automatically such as rerouting materials, reprioritizing orders, or triggering a supplier expedite request, always within your guardrails and defined rules.

-

What if our data isn’t perfect?

askPixi does not require flawless data. It cross-checks multiple sources to filter noise and identify true risks. If a feed goes down, for example a scanner stops reporting, it keeps working with the remaining inputs and flags the gap so you can address it.

-

How does it support shift and capacity planning?

askPixi adapts plans as conditions change. If a job finishes early, a machine goes offline, or priorities shift, it reallocates tasks, updates capacity forecasts, and can publish the changes instantly to digital boards or operator tablets so the floor always runs on the latest plan.

-

Is it suitable for different plant sizes?

Yes. In large plants askPixi coordinates complex flows across multiple lines and suppliers. In smaller facilities it cuts manual re-planning and keeps orders prioritized without extra admin load.

-

How is security handled?

All connections are encrypted. askPixi follows your existing user permissions and runs within your approved IT environment or secure cloud. No operational data is shared externally.

-

How much training of the AI is required?

Minimal. You can interact with askPixi in plain language without coding or special commands. Operators and managers typically get up to speed in a single onboarding session.

-

What kind of improvements is it built to deliver?

askPixi targets measurable operational gains such as higher throughput, fewer last-minute changes, better on-time delivery, less manual coordination, and greater schedule stability. Over time these gains accumulate into a more predictable and resilient operation.